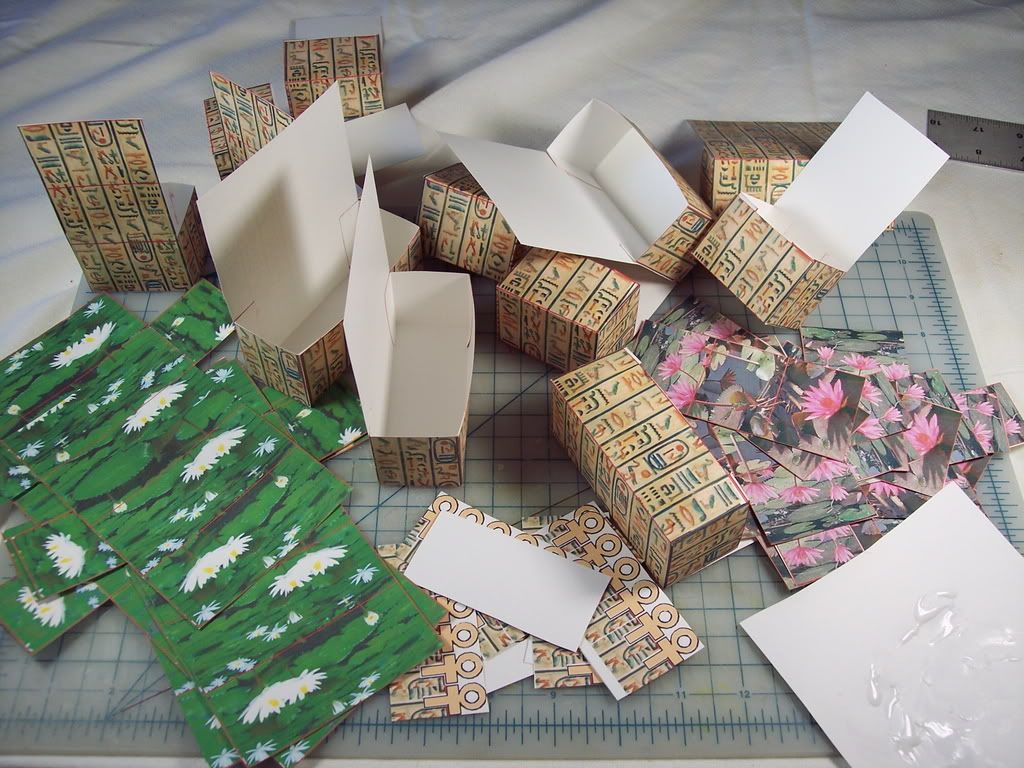

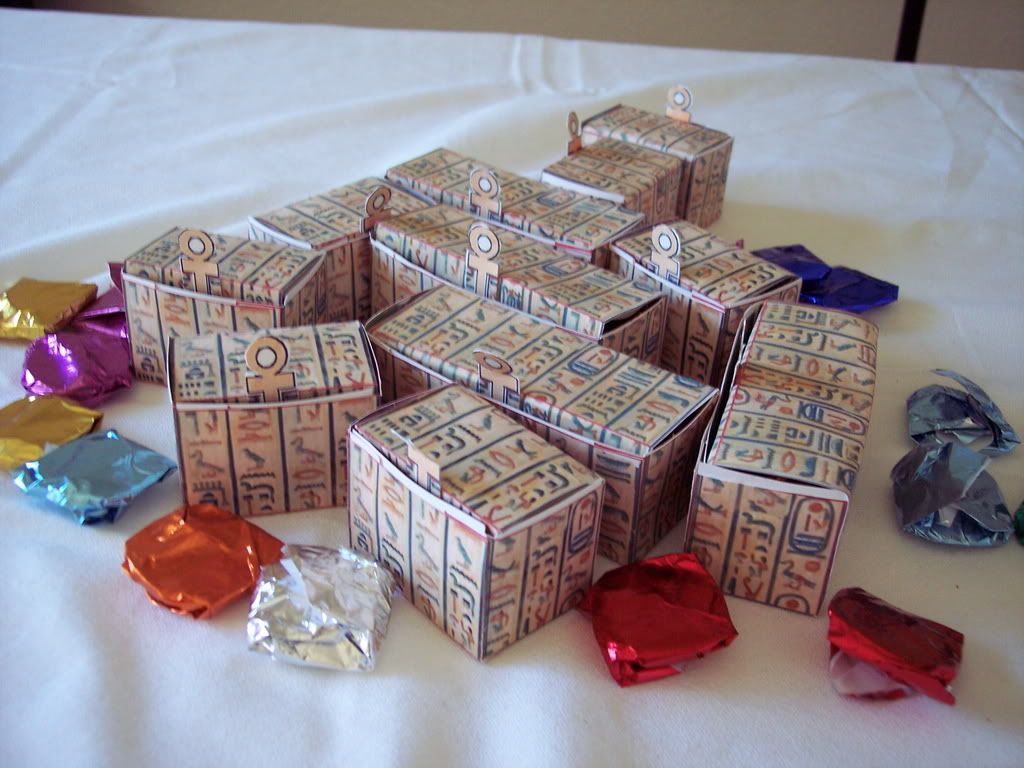

| Templates for the chocolate boxes, their outsides and their insides are separate Photoshop files. They're printed, cut, and glued together. The chocolate tempering process is not photographed. This time, a tempering machine was used. It brings the chocolate to the precise temperature for the type of chocolate being tempered, white, milk, or dark. The machine offers two methods of getting to the target temperature. Being a machine, it's able to bring the melted mass directly to the target temperature. It alerts the operator when to add seed chocolate to clue the melted mass to its crystalline structure. The second method is more traditional. It heats the melted mass slightly beyond the target temperature, then cools the mass slightly below the target temperature, alerts the operator to add seed chocolate and when to remove it, reaches the target temperature and alerts the operator when it's done. This same process can be speeded by using hot and cold water baths. The temperature ranges here are not far above and below body temperature. Care must be taken not to allow any water to enter the melted chocolate or the entire melted mass will seize most unfortunately in a way similar to how adding a small amount of water to a large amount of sugar seizes sugar into unmanageable lumps. The melting point of chocolate is slightly below body temperature. It's always described as a range of degrees rather than a steady precise number. That's because chocolate is a complex amalgam of fats and solids each with their own melting point. The producer of a particular chocolate provides the temperatures for tempering, a range of temperature for that particular chocolate, which itself is combination of chocolate from various sources. This is true even with single-source chocolates. It's analogous to variety resulting from micro-conditions experienced by vintners. (Actually, it true for all farm food.) Usually manufacturers combine cocoa beans from a variety of sources the same way coffee beans are combined in order for the final product over the long term of several runs to posses a somewhat subjectively vague but in some ways measurable and reliable consistency. It's an art, this wine, coffee and chocolate blending. But why bother tempering and not just melt it? When chocolate cools and hardens it crystalizes. The crystalline structure is analogous to stacked chairs set in neat rows. Bringing the temperature of melted chocolate up above its melting point then down to below it but still keeping it mostly liquid, then back up again just beyond the melting point (range), is like gently stroking it, almost like combing it. Sticking with chairs, it's like stacking them neatly and carefully instead of just tossing them carelessly all into a pile. The difference this makes is the wonderful snap the chocolate makes when it's broken and the shine imparted to the product when molded. |

No comments:

Post a Comment